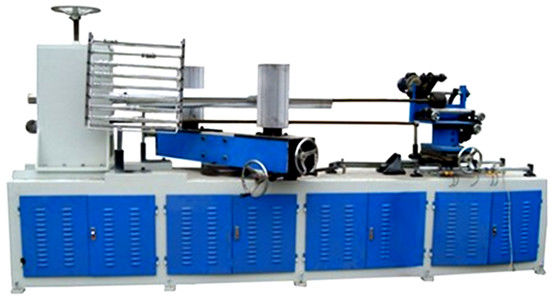

PLC Program Control Automatic Paper Tube Making Machine 25 Meters Per Min

Description

YY-300 Automatic Paper Tube Making Machine is specially designed for producting paper tubes, paper cores of different sizes, It is a necessary assistant equipment for toilet roll machine, kitchen towel machine and JRT products. You can make paper cores/tubes of different sizes on this machine, easy setting and adjustment by touch screen.

Compact design and easy adjustment help operators to have full control of functionality and production of the machine.

Technical Specification

| Paper Roll Stand |

Independent shelf for paper rolls hanging and. The quantity of shelves is according to the layers of paper. Normally, we provide paper roll stand for 8 layers of paper.

|

| Gluing Part |

There are two gluing ways that the customer can choose: single-side gluing, double-side gluing. The thickness of glue can be adjusted. Automatic gluing.

|

| Winding part |

Adopt two winding heads for winding. It is strong and powerful which can make hard and good paper tube.

|

| Driving part |

The two winding heads are driven by AC motor with strong power and stepless speed changing. The motor is driven by the vector frequency converter. It works stable and not to crash machine. Use a Worm Speed Reducer to increase the torsion so as to make sure the core winding is good.

|

| Cutting part |

Use Servo motor system for the cutter; automatic cutting. It can make the cutting very precise.

It adopts the high-hard knife for cutting. The cutting is complete and beautiful.

|

| Digital Process |

Adopts PLC with program for controlling; all the control buttons are gathered to a panel which make the operation convenient;

|

| Cutting Length | 20-20000mm |

| Cutting tolerance | ±1mm |

|

Core tube thickness |

1-10mm |

| Tube diameter | ф20—ф200mm |

| Motor speed | 0—1600rpm |

| Maximum gluing quantity | 15 layers |

| Power needed |

Voltage: 440V 60HZ Main motor: 7.5KW Hydraulic system: 2.2KW Servo motor: 1KW Cutter motor: 1/2HP

|

| Speed | Max. speed:25m/min |

Our Production Process and Delivery to Customer

We have our own CNC to do parts machining, and then shot blasting, we do baking paint for all the parts. Next we start the assembly, when the machines are finished, we will do the commissioning and test running. If customer will not come to our factory to check and approve, we will send machine photos and videos to customer for confirmation and approval before packaging and shipment.

![]()

After Sale Services

Spare Parts

YouYuan provides around-the-clock parts support to keep your napkin machines running.

Installation

We're here to get you started on the right foot.

Complete installation and start-up support

Start-up and calibration support

Staff training